FUTURE FORGED

We have professional mechanical engineers and technical staff who independently perform engineering analysis, calculations, and design for each wheel set.

Utilizes Aerospace-Grade Aluminum Forging

Edge Finishing and Coloring

Every component is refined without compromise, each one lifting the whole system forward.

Future Force Golf

Future Force Club Head

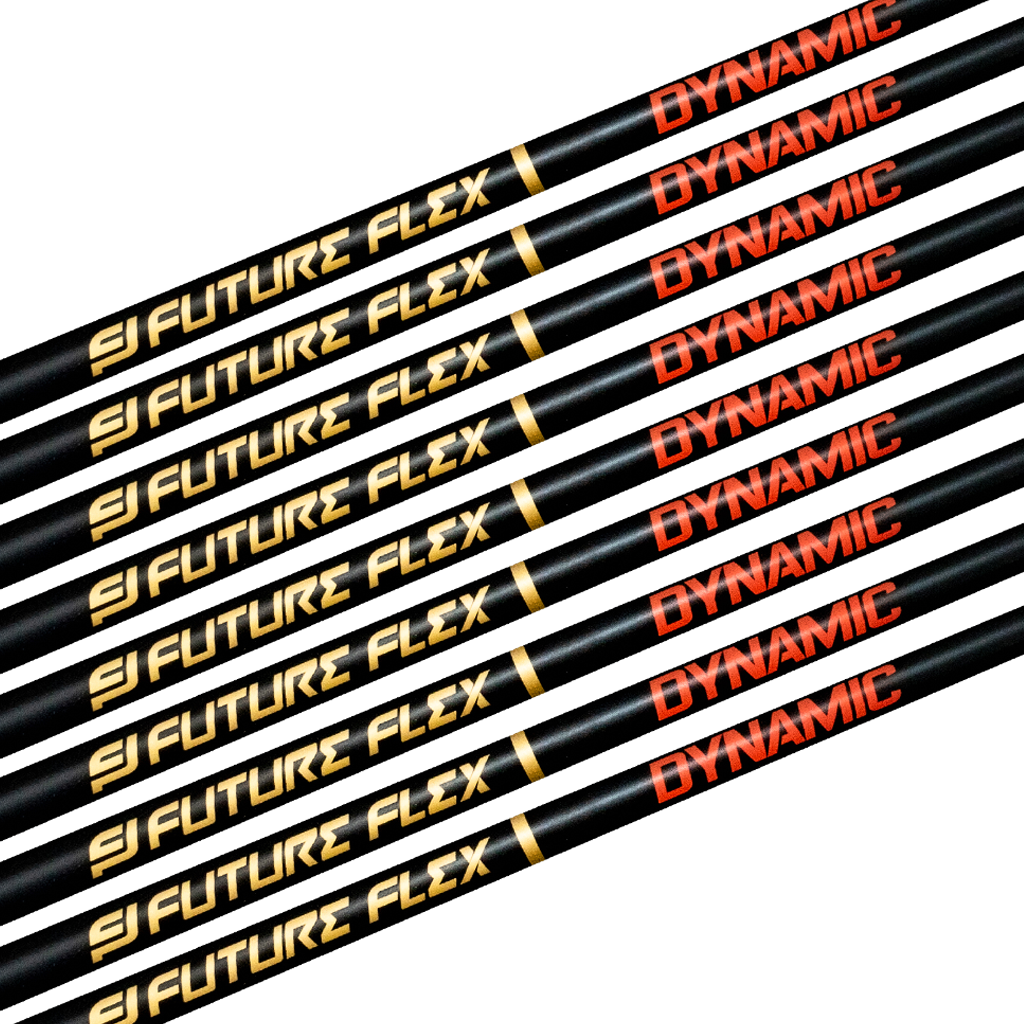

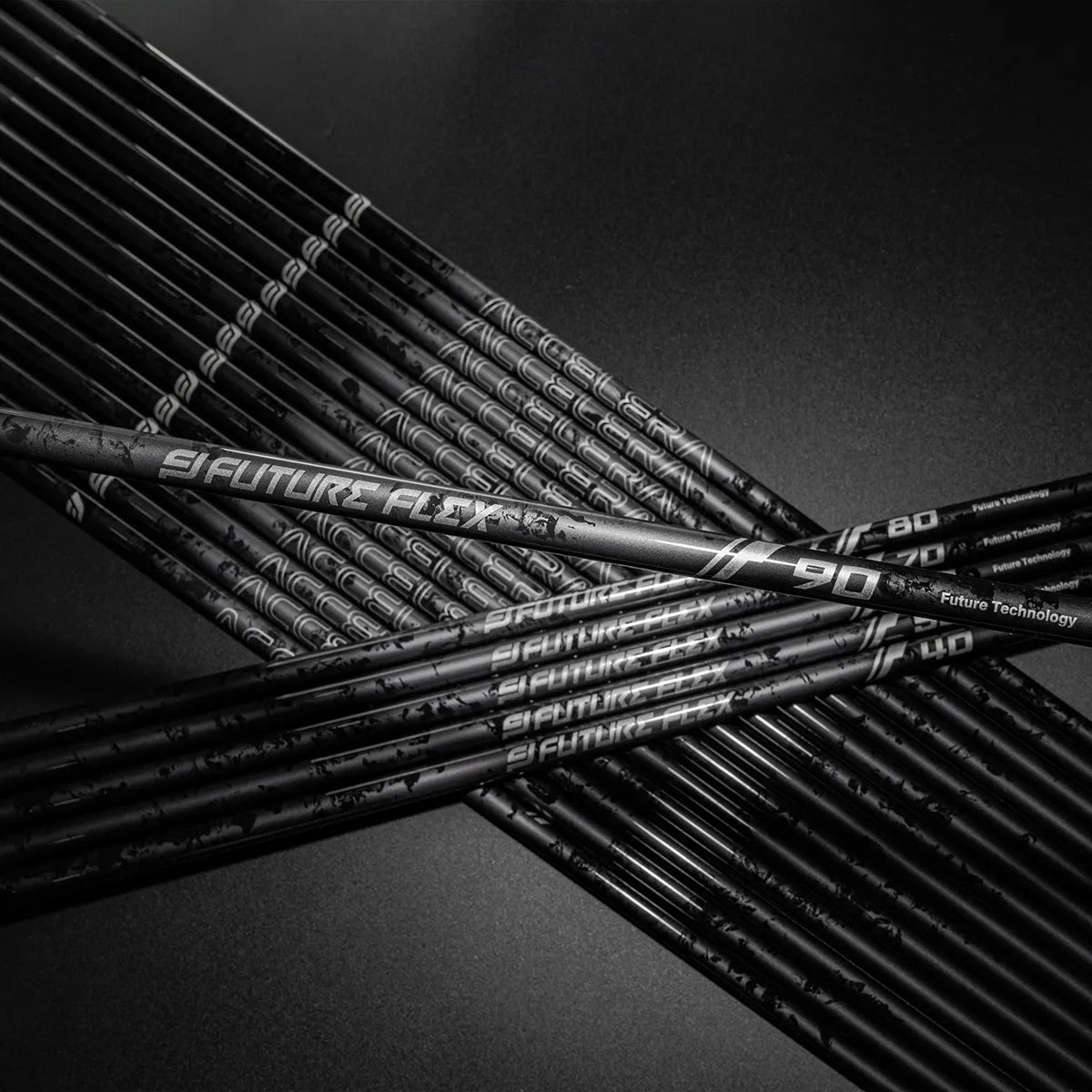

Future Flex Golf

Future Flex Golf Shaft

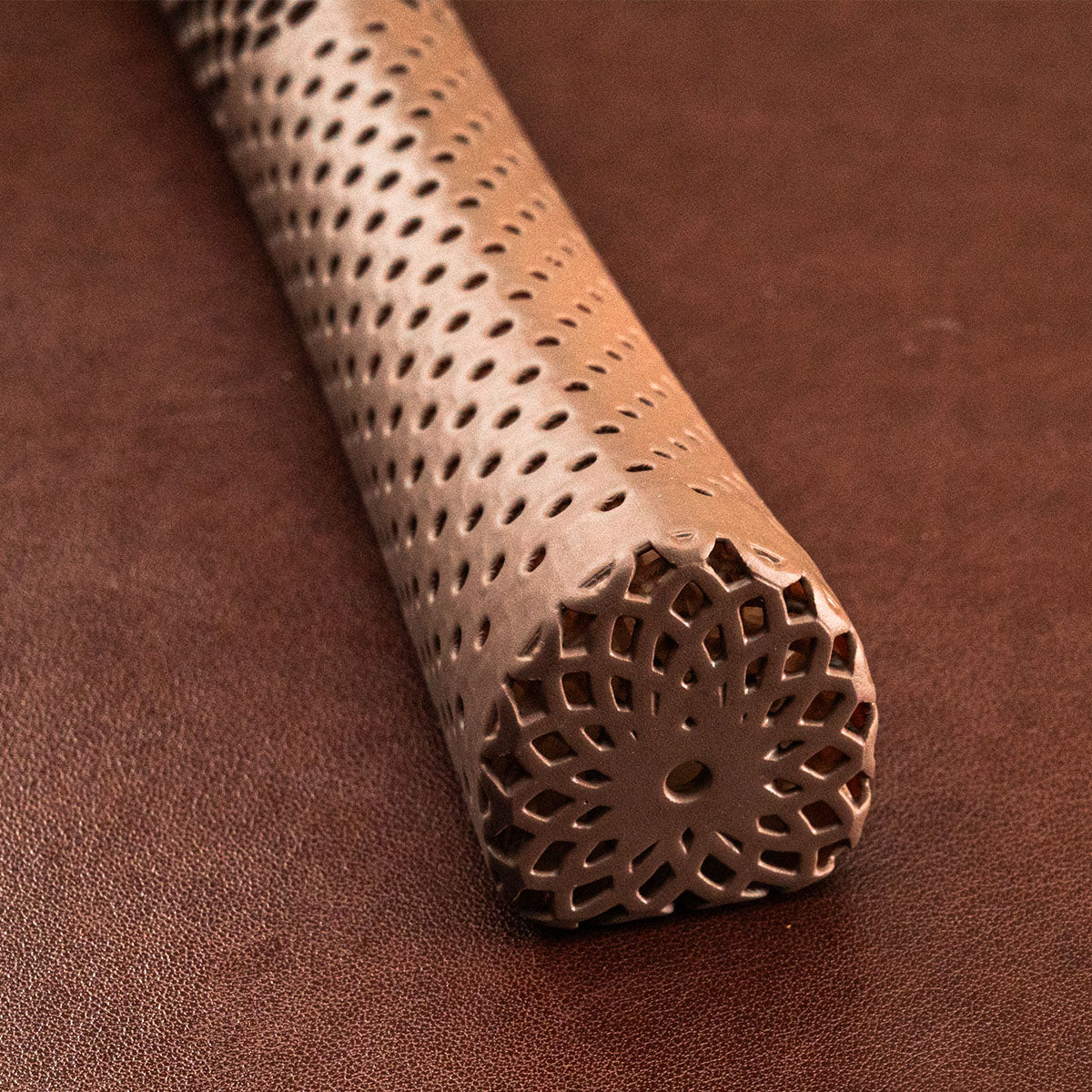

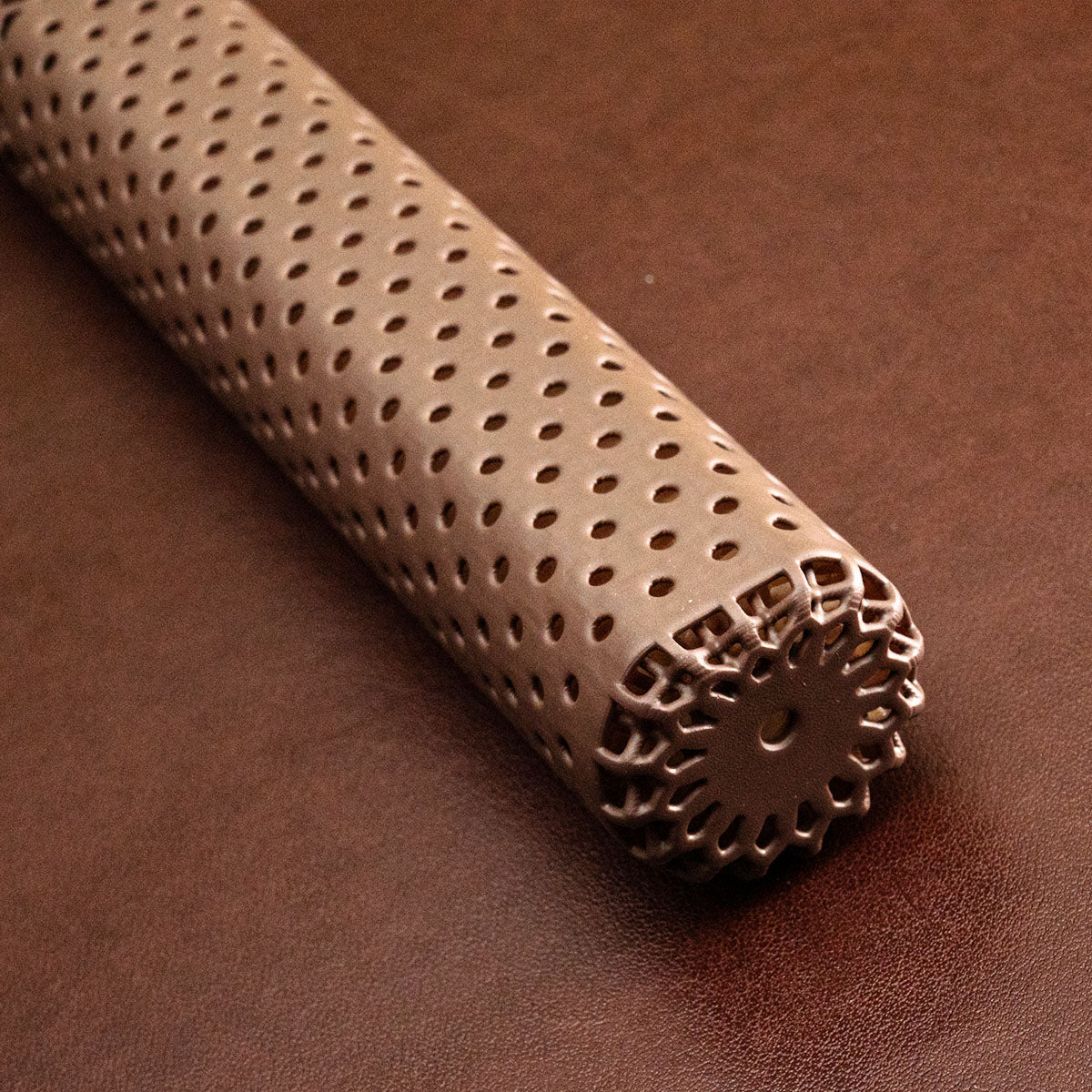

Point Eight Golf

Point Eight Golf Grip

DISCOVER|Four Drivers. Four Inner Souls.

Why Future Force Created Four Different Drivers Four driver heads. Four COR profiles. Four CNC face architectures. Discover how Future Force designs drivers for different swing types, distances, an...

Read more

FUTURE FORCE Black Stone – SUS303 LTD Putter

Future Force Black Stone SUS303 LTD – Japanese Steel CNC Blade Putter Crafted from Japanese SUS303 stainless steel and sculpted by full 5-axis CNC, the Black Stone LTD blends classic Japanese feel ...

Read more

FUTURE FORCE - Golf Putter - Black Damascus DSS LTD

Future Force Black Damascus DSS LTD – Limited to 20 Worldwide Crafted from forged Damascus steel and sculpted by full 5-axis CNC, the DSS LTD reveals its hidden wave patterns beneath a deep black f...

Read more